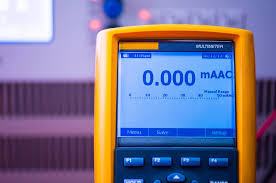

Electronic calibration services are essential for ensuring the accuracy and precision of electronic equipment. When it comes to calibrating electronic devices, expert calibration services can make all the difference in maximizing precision and reliability. By utilizing the expertise of professionals in electronic calibration services, businesses and individuals can ensure that their equipment is calibrated to the highest standard, resulting in reliable and accurate measurements. This article will explore the importance of expert electronic calibration services and how they can help in maximizing precision for various electronic devices.

Maximizing precision with expert electronic calibration services involves ensuring that electronic equipment is accurately calibrated to provide precise and reliable measurements. This process is essential for various industries, including manufacturing, aerospace, pharmaceuticals, and more. Expert electronic calibration services use advanced equipment and highly trained technicians to ensure that all electronic devices are calibrated to meet industry standards and regulations. This helps businesses operate efficiently and ensures the accuracy of their products and services. By partnering with expert electronic calibration services, companies can maximize the precision of their electronic equipment, leading to improved performance, reduced downtime, and overall cost savings.

The Importance of Electronic Calibration Services in Modern Industries

medical equipment calibration services

Electronic calibration services are essential in modern industries for ensuring accurate and reliable measurements of electronic equipment. These services help in maintaining the quality and consistency of measurements, which is crucial for meeting industry standards and regulations. With the increasing complexity of electronic systems and the demand for precision in measurements, electronic calibration services play a vital role in ensuring the proper functioning of equipment and the reliability of test results. Additionally, regular calibration helps in detecting and rectifying any deviations or inaccuracies in the performance of electronic equipment, thereby preventing potential issues and ensuring the overall efficiency of industrial processes. As a result, electronic calibration services contribute to the overall quality, safety, and compliance of modern industries.

Maximizing Efficiency with Electronic Calibration Services

Maximizing efficiency with electronic calibration services involves utilizing advanced technology and automated systems to streamline the calibration process. This includes precise measurement tools, software, and digital records to ensure accuracy and compliance with industry standards. Electronic calibration services can also improve turnaround times, reduce human error, and increase productivity by automating repetitive tasks. Additionally, electronic calibration services can provide real-time data and insights for better decision-making and maintenance planning. By leveraging electronic calibration services, organizations can optimize their operations, minimize downtime, and enhance overall efficiency.

Choosing the Right Provider for Electronic Calibration Services

When choosing the right provider for electronic calibration services, it is important to consider the provider's experience and expertise in the field. Look for a provider that has a proven track record of delivering high-quality calibration services for electronic equipment. Additionally, it is essential to ensure that the provider is accredited and compliant with industry standards and regulations. This can give you confidence that the calibration services meet the necessary requirements for accuracy and reliability. Consider the provider's turnaround time for calibration services, as well as their customer service and support capabilities. It is important to work with a provider that can efficiently handle your calibration needs and provide responsive support when required. Cost is also a significant factor to consider when choosing a calibration service provider. While it is important to stay within budget, be cautious of providers with significantly lower prices, as this could indicate a compromise in quality. Ultimately, thorough research and due diligence can help you select the right provider for electronic calibration services, ensuring that your equipment is accurately calibrated and maintained to the highest standards.

Understanding the Benefits of Electronic Calibration Services

Electronic calibration services are crucial for ensuring the accuracy and reliability of electronic equipment and instruments. These services involve the use of sophisticated technology and highly trained technicians to compare the measurements of a device to a standard, and make necessary adjustments to bring it back into alignment. There are several benefits to using electronic calibration services. Firstly, it ensures that equipment is operating within specified tolerances, which is essential for industries such as aerospace, automotive, healthcare, and manufacturing. This helps to prevent costly errors and production delays that can result from inaccurate measurements. Additionally, electronic calibration services can help to extend the lifespan of equipment by identifying and correcting issues before they become serious problems. Regular calibration can also improve the overall performance of equipment, leading to higher quality output and greater customer satisfaction. Furthermore, utilizing electronic calibration services can help companies comply with industry regulations and standards. Many industries are required to have their equipment calibrated on a regular basis to ensure accuracy and safety. Overall, electronic calibration services are an important investment for any organization that relies on precision measurement equipment. By ensuring the accuracy and reliability of electronic instruments, companies can improve their operational efficiency, reduce downtime, and ultimately save money in the long run.

Improving Accuracy and Precision through Electronic Calibration Services

Electronic calibration services are designed to improve the accuracy and precision of electronic equipment by ensuring that the readings and measurements provided by these devices are reliable and consistent. This is achieved through the use of specialized calibration equipment and procedures that are able to detect and correct any deviations from the intended performance of the electronic instruments. By regularly calibrating electronic equipment, businesses can minimize the risk of errors in their measurements and ensure that their processes and products meet the required standards. This is particularly important in industries such as manufacturing, healthcare, and telecommunications, where precise measurements are essential for the safety and quality of products and services. Electronic calibration services can also help businesses comply with industry regulations and standards, as many regulatory bodies require that electronic equipment be regularly calibrated to ensure accurate and reliable performance. Additionally, electronic calibration services can help extend the lifespan of electronic equipment by detecting and addressing any potential issues before they become critical. Overall, electronic calibration services are an important aspect of quality assurance and can help businesses improve their operational efficiency, reduce the risk of errors, and maintain compliance with industry standards and regulations.

Streamlining Processes with Professional Electronic Calibration Services

Streamlining processes with professional electronic calibration services involves partnering with a reputable calibration service provider to ensure that all equipment and instruments are maintained and functioning accurately. This can help to reduce downtime, improve productivity, and minimize the risk of errors or inaccuracies in measurements and data. Professional calibration services utilize advanced technology, industry-standard procedures, and experienced technicians to ensure that all equipment is calibrated to the required specifications. This helps businesses maintain compliance with industry regulations and standards, ultimately enhancing operational efficiency and product quality.

The Role of Electronic Calibration Services in Quality Control<

instrument calibration services/h2>

Electronic calibration services play a critical role in quality control by ensuring that electronic equipment and instruments are operating within required specifications. Calibration services help to verify the accuracy and precision of electronic devices, such as measuring tools, testing equipment, and sensors. This is essential for maintaining consistent and reliable measurements, which is crucial in industries such as manufacturing, healthcare, and aerospace. By regularly calibrating electronic devices, companies can ensure the quality of their products and processes, as well as comply with regulatory standards. Electronic calibration services also provide traceable documentation, which is important for demonstrating the reliability of measurements to customers, regulatory agencies, and accreditation bodies. Overall, electronic calibration services are a vital aspect of quality control, ensuring that electronic equipment performs to expected standards and facilitates accurate and reliable measurements.

Investing in Electronic Calibration Services for Long-Term Success

Investing in electronic calibration services for long-term success is essential for industries that rely on accurate and precise measurements. These services ensure that electronic instruments and equipment are calibrated to meet industry standards, regulatory requirements, and specific application needs. By investing in electronic calibration services, businesses can minimize downtime, reduce risk and comply with quality and safety standards. Additionally, regular calibration can help extend the lifespan of electronic equipment, improve accuracy, and facilitate better decision-making. Overall, electronic calibration services are a critical investment for long-term success in industries such as manufacturing, aerospace, automotive, healthcare, and more.

Meeting Regulatory Standards with Electronic Calibration Services

Meeting regulatory standards with electronic calibration services involves ensuring that all electronic equipment used in a regulated industry meets the required precision and accuracy. This can include regular calibration of testing and measurement instruments to ensure they provide reliable and traceable results. Electronic calibration services also help to maintain compliance with industry-specific regulations and standards, such as ISO, FDA, and NIST. Compliance with these standards is crucial for ensuring the safety, efficacy, and quality of products and services. Calibration services help to minimize the risk of non-compliance and ensure that electronic equipment meets the necessary standards and requirements.

Key Considerations for Implementing Electronic Calibration Services

Some key considerations for implementing electronic calibration services include ensuring that the electronic calibration system is compliant with industry standards and regulations, integrating the electronic calibration system with existing workflows and systems, providing adequate training and support for personnel who will be using the system, establishing clear processes and protocols for calibration procedures, and regularly updating and maintaining the electronic calibration system to ensure accuracy and reliability. Additionally, considerations should be made for data security and integrity to protect sensitive calibration information. Finally, the costs and benefits of implementing electronic calibration services should be carefully evaluated to determine the return on investment for the organization.